0102030405

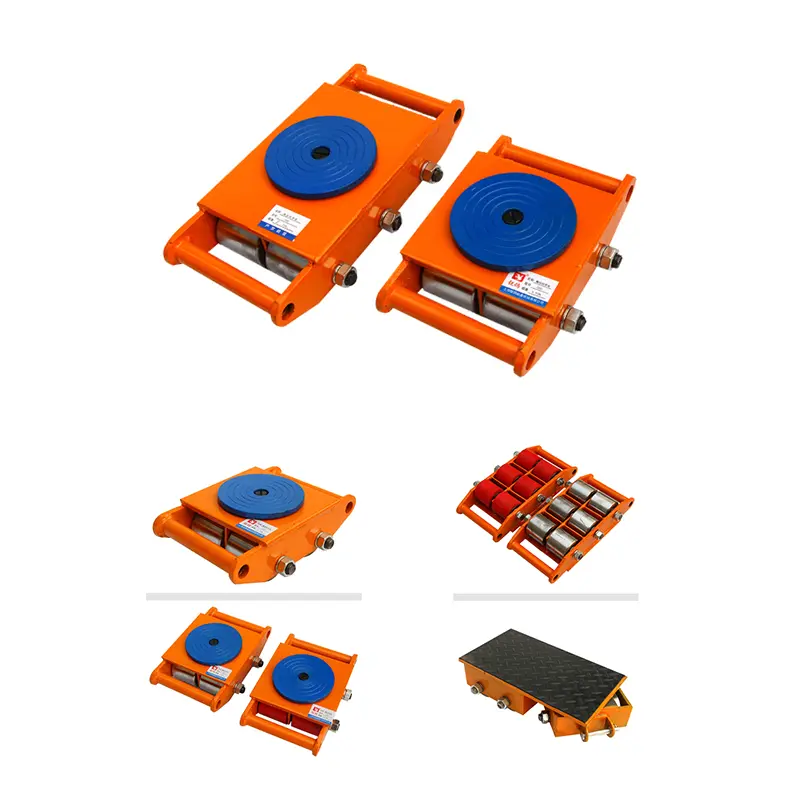

Steel Wheel Transport Vehicle

Working Principle

The working principle of steel wheel handling vehicles is mainly based on the principle of hydraulic transmission, which controls the hydraulic system to achieve handling, movement and other operations.

Here Is a Detailed Explanation

Hydraulic system composition: The hydraulic system of a steel wheel transport vehicle usually consists of key components such as an oil tank, motor, pump, valve, and hydraulic cylinder. When the motor is running, the pump will suck oil from the tank and press it into the high-pressure oil circuit. Through precise adjustment and distribution of valves, the oil generates strong forces in the hydraulic cylinder, thereby driving various functions of the transport vehicle.

Handling Process

Lifting: By controlling the hydraulic system, the steel wheel handling vehicle can use a main hook or similar device to lift heavy goods (such as steel plates, pipes, etc.) and steadily move them to the destination. This process relies on the strong lifting force generated by the hydraulic cylinder.

Mobile: The walking mechanism of the transport vehicle is also driven by a hydraulic system. The hydraulic motor and gear transmission device work together to enable the transport vehicle to move smoothly to the designated position. This design ensures that the handling vehicle can maintain flexibility and stability even under heavy loads.

Tilt and adjustment: The hydraulic system also allows the handling vehicle to tilt and adjust during handling tasks to accommodate goods of different shapes and sizes. By controlling the extension and retraction of the hydraulic cylinder, the tilt angle and position of the goods can be accurately adjusted to ensure the safety and efficiency of the handling process.

Operation control: The operation of steel wheel handling vehicles is usually completed by manipulating the control system. The operator can adjust the parameters of the hydraulic system, such as pressure, flow rate, etc., as needed to achieve precise control of various functions of the transport vehicle. This design enables the handling vehicle to adapt to a variety of different working environments and task requirements.

In summary, the working principle of steel wheel handling vehicles mainly relies on the powerful functions and precise control of the hydraulic system. By using a hydraulic system to perform lifting, moving, tilting, and other operations, the handling vehicle can efficiently and safely complete various handling tasks.

Scope of Use

The main uses of steel wheel trucks include heavy object handling, equipment handling, and mechanical handling. It is particularly suitable for the movement of heavy goods, which can save a lot of manpower and time, especially when handling large equipment or equipment with long distances. It is more effective when used in conjunction with pry bars or jacks, and crossbars. In addition, steel wheel handling vehicles can also be used for the installation of heavy equipment in place, sometimes replacing gantry frames.

Applicable Scenarios

Steel wheel trucks are widely used in the following scenarios:

Used in industries such as machine tools, bridge equipment, and construction engineering for heavy object handling, it can be paired with claw jacks to improve handling efficiency.

Warehouses, factories, shopping malls, and other places that require stacking, handling, and palletizing are suitable for the movement and storage of various heavy goods.

Characteristic

The characteristics of steel wheel transport vehicles include:

Strong bearing capacity: using alloy steel wheels, compressive and wear-resistant, with a long service life.

Strong flexibility: It can be used individually or in combination with multiple units to adapt to different handling needs.

Wide applicability: Suitable for the handling and installation of various heavy equipment, especially performing well in complex environments.

Vehicle size: 280*210*105

Types of Wheel

Technical Parameters

Straight Tank Parameters

Model |

Load capacity limit(T) |

Common load-bearing capacity |

No. of wheels |

Wheel size |

L*W*H(mm) |

Weight(Kg) |

CRD6 |

6T |

3T |

4 |

80*70 |

300*225*110 |

11.6 |

CRD8 |

8 |

4T |

6 |

80*70 |

400*225*110 |

16.8 |

CRD12 |

12 |

6T |

8 |

80*70 |

500*25*110 |

21.6 |

CRD15 |

15 |

7T |

9 |

80*70 |

400*313*110 |

23.5 |

CRD18 |

18 |

9T |

12 |

80*70 |

500*313*110 |

32 |

Steering Tank Parameters

Model |

Load capacity limit(T) |

Common load-bearing capacity |

No. of wheels |

Wheel size |

L*W*H(mm) |

Weight(Kg) |

CRD6 |

6T |

3T |

4 |

80*70 |

385*263*110 |

17.4 |

CRD8 |

8T |

4T |

6 |

80*70 |

470*263*110 |

23.6 |

CRD12 |

12T |

6T |

8 |

80*70 |

470*263*110 |

25.8 |

CRD15 |

15T |

7T |

9 |

80*70 |

470*263*110 |

36.1 |

CRD18 |

18T |

9T |

12 |

80*70 |

470*263*110 |

38 |

Product Details

Seamless welding rod

Quenched bearing link, no worries about breakage during use, rest assured and reliable

Can install control lever

Easy to operate, time-saving and labor-saving to improve handling efficiency, and more flexible steering

Heat treated screws

Carefully manufacture heat-treated screws

Long usage time

Quenching axis

The central axis has undergone quenching treatment

Rest assured to use