0102030405

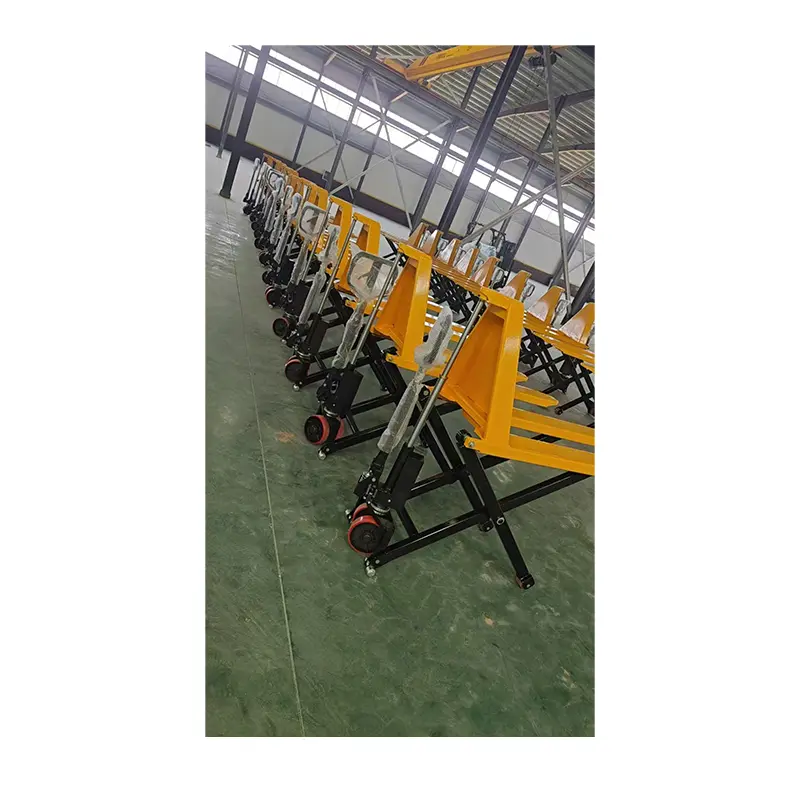

Scissor Handling Forklift Type-Manual High Lift Handling Forklift

Working Principle

The working principle of a scissor lift truck mainly includes the following aspects:

Hydraulic system drive: Shear trucks usually use a fully hydraulic drive system. Hydraulic oil enters the lower end of the hydraulic cylinder through the oil filter screen, explosion-proof electromagnetic directional valve, throttle valve, hydraulic control check valve, and balance valve, causing the piston of the hydraulic cylinder to move upward, thereby lifting heavy objects. The return oil at the upper end of the hydraulic cylinder returns to the oil tank through an explosion-proof electromagnetic directional valve, and the rated pressure is adjusted through an overflow valve.

Operation process: When operating the scissor lift truck, first open the electrical box door, turn the hydraulic station switch to the manual position, press the start button, and after the motor runs, brake and power off. Pressing the descent button (i.e. emergency stop switch) will cause the motor to stop running and emit an alarm sound. Release the up or down button (i.e. emergency stop switch), and when the machine is in a free state, press the emergency stop switch once to stop the machine.

Safety features: The scissor lift truck is designed with various safety features, such as an adjustable stabilizer that automatically activates when lifting goods above 400 millimeters, ensuring optimal stability and braking performance. When the load is less than 250 kilograms, the quick lift function will double the lifting speed. In addition, the ergonomic handle design is adopted to make the operator more comfortable and effortless.

Scope of Use

The oil cylinder, cargo shaft, handle, shaft seat, bearings, pins, nuts and other components are all made of stainless steel materials. The electric series adopts maintenance free starting batteries from Johnson Controls in the United States, saving maintenance time and costs. Charging is convenient, fast and long-lasting, with a charged capacity display meter and a low voltage alarm light.

Electric charger: built-in charger.

Suitable for meat processing and other food industries, acidic and saltwater environments.

Characteristics

Board thickness: 10

Wheel material: PU wheel

Weight: 155

Maximum driving speed: 0.6

Number of wheels: 2

Steel plate thickness: 10mm

Walking method: Hand push walking

Special industry: manual forklift

Maximum lifting speed: 20-30s

Item number: Manual high lift handling truck

Lowest position of fork: 85mm

Fork size: 520*1150/680*1150mm

Newly upgraded high lift hydraulic handling vehicle

Up to 800mm·effective lifting height ton level load-bearing frame, thick and durable quality oil cylinder, labor-saving and fast improvement.

Advantages

Authentic materials

Thick steel plates, pipes, etc. are all selected from high-quality steel from Baosteel

Welding

Strict and rigorous

The welding process is seamlessly welded by automated welding robots, ensuring reliability.

Shot blasting

Strengthen processing, shot blasting process can enhance product rust removal and strengthen its service life.

Cylinder

Effortless and durable.

Sealed pressure resistant oil cylinder can avoid oil leakage and consolidate safety performance.

Painting

Rust resistant and durable.

Further consolidate the corrosion resistance of the product through high-temperature baking paint spraying.

Leak proof oil cylinder

Built in awesome sealing parts, with extraordinary leak proof performance, and durable service life after internal testing.

The handle of the human-machine engineering design has a moderate ground clearance and comfortable grip, and the baffle has good support.

Flexible configuration.

Comfortable human-machine handle.

Stamped fork.

Security

Featuring stable performance, safety assistance and good load-bearing capacity.

We provide strong support for your various handling tasks

Technical Parameters

Parameters |

Unit |

1.0T |

1.5T |

||

Rated load |

Kg |

1000 |

1000 |

1500 |

1500 |

Forklift lifting height |

mm |

800 |

800 |

800 |

800 |

Fork lowering height |

mm |

100 |

100 |

100 |

100 |

Fork length |

mm |

1100 |

1200 |

1100 |

1200 |

Single fork width |

mm |

160 |

160 |

160 |

160 |

Fork outer width & fork inner width |

mm |

550 |

685 |

550 |

685 |

Thickness of fork steel plate |

mm |

230 |

365 |

230 |

365 |

Front wheel specifications |

mm |

3.5 |

3.5 |

3.75 |

3.75 |

Rear wheel specifications |

mm |

ᶲ180*50 |

ᶲ180*50 |

ᶲ180*50 |

ᶲ180*50 |

Wheel specifications |

mm |

ᶲ80*70 |

ᶲ80*70 |

ᶲ80*70 |

ᶲ80*70 |

Wheel materials |

/ |

Polyurethane/Nylon |

Polyurethane/Nylon |

Polyurethane/Nylon |

Polyurethane/Nylon |

Vehicle length |

mm |

1500 |

1600 |

1500 |

1600 |

Vehicle wide |

mm |

565 |

700 |

565 |

700 |

Vehicle height |

mm |

1200 |

1200 |

1200 |

1200 |

Vehicle weight |

Kg |

107 |

115 |

116 |

123 |