0102030405

Permanent Magnet Suction. Permanent Magnet Chuck

Working Principle

The working principle of permanent magnet suction cups is based on the continuity principle of magnetic flux and the superposition principle of magnetic field. The magnetic circuit of the permanent magnet suction cup is designed as multiple magnetic systems, and through the relative motion of the magnetic systems, the magnetic field strength on the working magnetic pole surface is added or cancelled, thereby achieving the purpose of suction and unloading.

Specifically, when the permanent magnet suction cup is in a magnetic suction state, the magnetic field lines come out of the N pole of the magnet, pass through the magnetic yoke, pass through the ferromagnetic workpiece, and then return to the S pole of the magnet through the magnetic yoke.

In this way, the workpiece is firmly attracted to the working pole surface of the permanent magnet suction cup. When unloading is required, the magnetic pole is in a demagnetized state, and the magnetic field lines do not form a closed loop on the working pole surface. Almost no magnetic field lines come out from the working pole surface, so there is no suction force on the workpiece, thus achieving smooth unloading.

In addition, permanent magnet suction cups usually use high-performance rare earth materials such as neodymium iron boron as the core, which have the characteristics of physical principles, strong controllability, low production cost, corrosion resistance, and better waterproof performance than electromagnetic suction cups. These characteristics make permanent magnet suction cups widely used in fields such as mechanical processing and mold manufacturing.

Scope of Use

Permanent magnet suction cups have a wide range of applications in various fields and scenarios. The following are its main uses:

Mechanical processing industry: In machining processes such as turning, milling, grinding, and drilling, permanent magnet suction cups are used to firmly attach and fix metal workpieces, ensuring machining accuracy and stability.

Mold manufacturing industry: During the processing, assembly, and repair of molds, permanent magnet suction cups can effectively fix various components of the mold.

Steel structure manufacturing industry: used for lifting and installing steel structural components such as steel beams and plates.

Automotive manufacturing industry: In the production process of automotive components, such as engine cylinder blocks, cylinder heads, crankshafts, etc., they play a role in fixing and positioning.

Shipbuilding industry: auxiliary processing and assembly of ship components, as well as lifting of ship sections.

Aerospace industry: used for the manufacturing and maintenance of aircraft components, ensuring high-precision machining and assembly requirements.

Electronic equipment manufacturing industry: Assembling and testing fixed electronic components.

Hardware manufacturing industry: used for processing and organizing screws, nuts, and small hardware components

Logistics and warehousing industry: used for handling and organizing magnetic material goods.

Equipment maintenance industry: used to fix parts for maintenance operations when repairing large mechanical equipment.

In addition, permanent magnet suction cups have various application scenarios in daily life:

Home cleaning: used for cleaning windows, glass, floors, etc., due to its strong adhesion and stability, making cleaning work more convenient and efficient.

Building block toys: By using magnetic attraction and repulsion, building blocks are more firmly combined together, increasing the fun of construction and cultivating children's hands-on ability and creativity.

Furniture decoration: used to fix decorative items on the wall such as clocks, mirrors, etc., avoiding nail holes on the wall and reducing damage to the wall.

Electronic product bracket: supports and secures electronic products such as smartphones and tablets, making it convenient to use and saving space.

Automotive accessories: used for fixing interior decorations and storage boxes to enhance driving safety.

Medical devices: used for fixing and supporting medical devices, providing convenience and stability during surgical procedures.

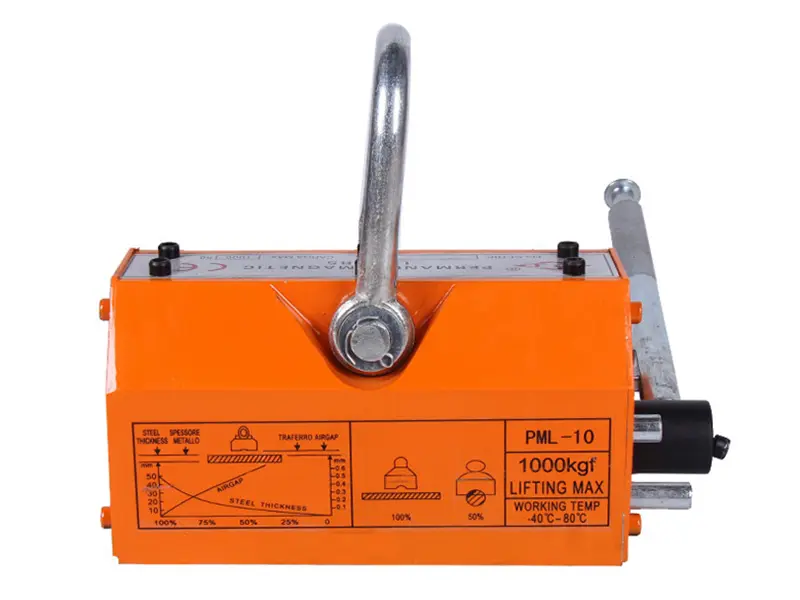

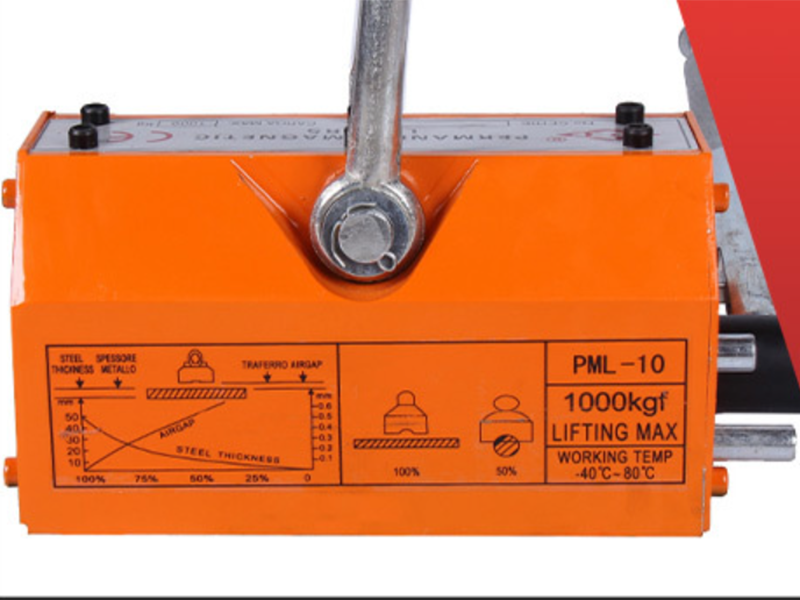

Product attributes

Scope of application: Ship assembly, handling of machined parts, warehouse material management, loading and unloading of goods, transportation of plates, lifting of steel plates, installation of steel structures, maintenance of heavy equipment, bridge construction, manufacturing of metal products

Lifting height 3-30m

Increase by 1000kg