0102030405

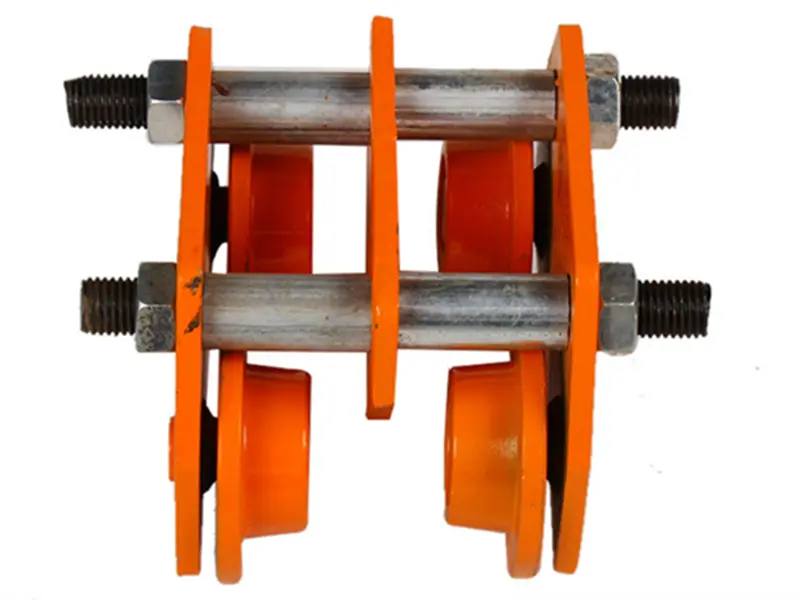

Mobile Manual Monorail Trolley-Slide down Trolley

Features

Lifting capacity: 1-20T

Lifting height: 3.0m Hand pushed sports car

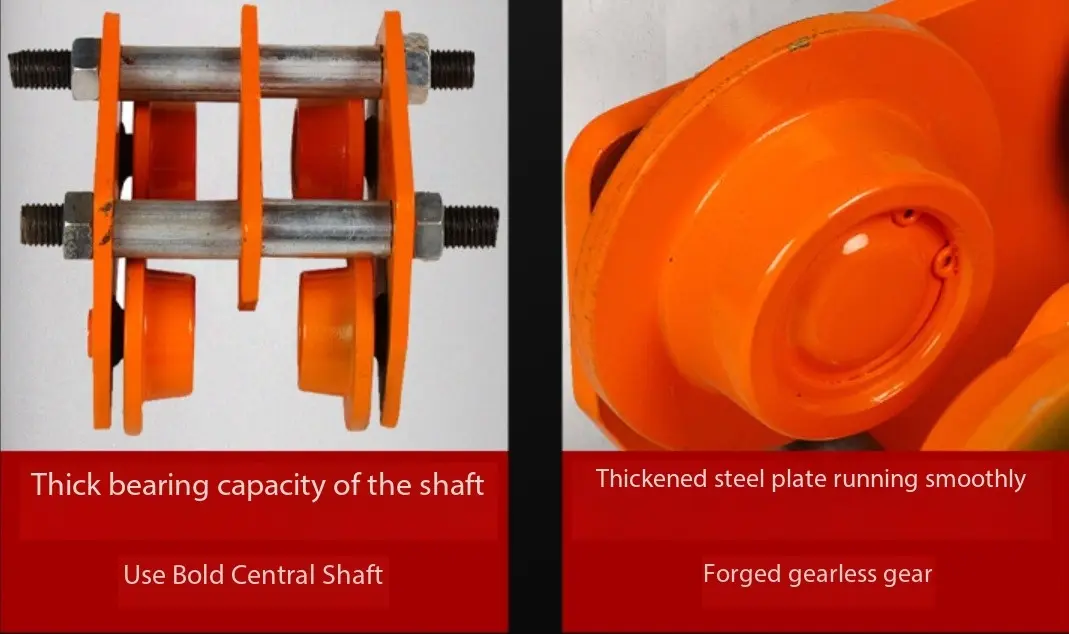

Thickened steel plate.

Strong load-bearing capacity.

Reasonable structure

Product Analysis

Easy to install

Safety use.

Small size.

High transmission rate.

Thickened steel plate.

Low hand tension.

Use

In different factories, mines, warehouses and other places.

Working Principle

The working principle of monorail mainly includes the following aspects:

Suspension system: Monorail trains usually use a suspension system, where the vehicle is suspended on a single track through rubber tires or air springs. This suspension system can provide good stability and ride comfort.

Guidance device: The guidance device of a monorail train usually includes guide wheels and guide arms. The guide wheels are fixed at the bottom of the vehicle, in close contact with the track, ensuring that the train travels along the track. The guiding arm is used to adjust the direction of the train and maintain its stable movement on the track.

Driving method: There are two main driving methods for monorail trains: one is motor-driven, which drives the wheels to rotate through the electric motor; Another type is direct drive, which means there is a driving device on the track that transmits power to the wheels through a transmission device.

Safety measures: Monorail trains are usually equipped with safety devices such as emergency braking systems and collision avoidance devices to ensure rapid stopping or avoid collisions in emergency situations. In addition, sensors and monitoring devices may also be installed on the track to monitor the real-time operation status of the train.

Maintenance and upkeep: The maintenance and upkeep work of monorail trains includes regular inspections of the track condition, replacement of worn parts, cleaning of vehicles and tracks, etc. These tasks require professional technicians to ensure the normal operation of trains and the safety of passengers.

Scope of Use

The main working purpose of monorail is lifting and hoisting. Monorail trains are usually installed on I-beam tracks to fix lifting hoists and achieve the lifting and lateral movement of heavy objects. Specifically, monorail trains can not only perform lifting and lowering operations in the vertical direction, but also move horizontally, making them widely used in places such as factories and warehouses where heavy objects need to be frequently moved.

In addition, the design of the monorail allows it to maintain a safe distance during operation, reducing the physical exertion of operators and potential safety risks. For example, wireless remote control monorail trains transmit commands through signal induction, and operators can control them from a distance away from the work area to ensure their safety. This design not only improves work efficiency, but also enhances the safety of homework.

Description

Thick steel wheels run smoothly.

Bold central axis.

Multiple options to meet different customer needs.

Technical Parameters

Rated load capacity |

Applicable I-beam models |

Hand pulled trolley net weight/Kg |

Hand pulled trolley packaging size/mm |

Hand pushed trolley net weight/Kg |

Hand pushed trolley packaging size/mm |

0.5T |

10-20 |

- |

- |

4 |

200*190*140 |

1.0T |

10-20 |

9 |

230*210*170 |

6 |

220*200*160 |

2.0 |

16-25 |

12.5 |

270*240*200 |

10 |

250*240*170 |

3.0T |

20-36 |

22 |

300*300*210 |

19 |

300*270*210 |

5.0T |

22-55 |

37 |

360*290*260 |

35 |

350*280*260 |

10T |

36-55 |

52 |

370*370*330 |

48 |

370*370*330 |

20T |

36-55 |

155 |

900*600*380 |

- |

- |

Product Details

Bold chain

Manganese steel forging, precision quenched chain with strong tensile strength, not easy to deform, not easy to fall off.

Installation hole design

The enlarged installation hole design is suitable for various devices, making it convenient, fast, and versatile to use.

Multiple models are convenient

Two modes and multiple models are more convenient to use, with a wide range of applications.

Overall spray coating

Adopting an overall spray coating design, it is corrosion-resistant and not easy to rust, with a long service life.