Inquiry

Form loading...

-

E-mail

-

Whatsapp

In today's fast-paced industry, maximizing the efficiency of a Manual Chain is crucial. John Smith, a leading expert in chain operations, once remarked, "Understanding the manual chain's mechanics can boost productivity significantly." This statement underscores the need for a strategic approach to manual chain usage.

Efficient operation hinges on proper technique and awareness. Many workers underestimate the importance of regular maintenance. Neglecting this can lead to unnecessary wear and inefficiencies. Small adjustments can yield significant improvements. A well-lubricated chain moves fluidly, enhancing overall workflow.

Additionally, understanding load limits is vital. Overloading a Manual Chain can result in failures and downtime. Operators often push boundaries without realizing the risks. Reflecting on these factors can lead to better practices. Embracing a proactive mindset can transform efficiency levels.

Using a manual chain effectively begins with understanding its basic components. The chain consists of interconnected links. Each link plays a crucial role in strength and flexibility. You need to know how to inspect the links regularly. Look for signs of wear or tear. A worn-out link can cause failure when under pressure.

Another key aspect is the tension. Proper tension is vital for efficiency. If the manual chain is too loose, it may slip. If it’s too tight, it can wear down faster. Finding the right balance requires practice. Adjusting the tension can be a trial-and-error process. Sometimes, the adjustments made can be too much or too little, which affects performance.

You must also consider the environment where you use the manual chain. Conditions such as humidity and temperature can impact its performance. Regular maintenance is necessary. Lubrication helps in reducing friction. However, too much lubricant can attract grime. Each situation requires reflection and adjustment. Understanding these basics allows for better usage and longevity of the manual chain.

Choosing the right type of manual chain is crucial for both efficiency and safety. Different applications require different types of chains. For instance, a lifting chain typically made from high-strength steel can handle heavy loads. According to an industry report, over 70% of workplace accidents occur due to improper equipment use. Selecting the appropriate chain can mitigate these risks.

Material is also an important factor. Chains made from alloy steel offer increased resistance to wear and corrosion. This can lead to a longer lifespan and reduced replacement costs. However, they may be heavier, potentially affecting maneuverability. In a survey, 65% of workers reported difficulty with chain handling due to weight. Reflecting on this can help companies streamline operations and improve safety protocols.

Additionally, understanding load capacity is essential. Each chain is rated for a specific weight. Exceeding this limit can lead to failure, risking injurious incidents. Observing these guidelines can aid businesses in maintaining a safe environment. Still, many neglect this crucial aspect, leading to dire consequences. Frequent training and evaluation of current chains should be a priority.

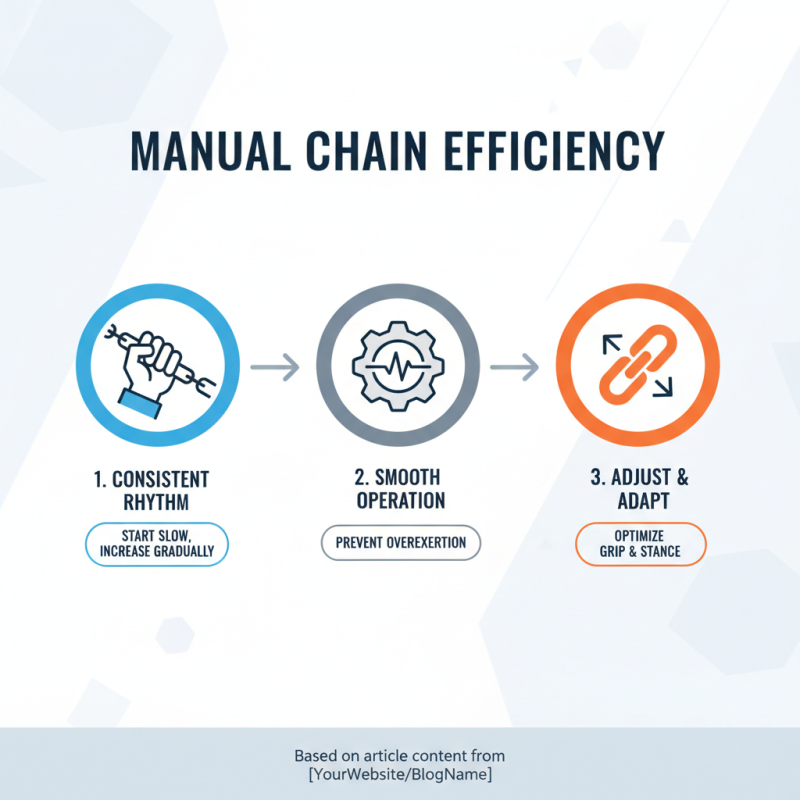

Using a manual chain efficiently requires mastering several key techniques. One crucial aspect is maintaining a consistent rhythm while operating the chain. Begin slowly to establish control before gradually increasing speed. This practice helps prevent overexertion and reduces errors. Pay attention to how the chain moves. If it feels jerky or unresponsive, adjust your grip or stance.

Another essential technique is to keep your equipment clean. Dirt and debris can significantly impact chain performance. Regularly inspect for wear and tear, and replace worn components as needed. This preventive maintenance can save time and frustration later. Be mindful of your surroundings too. Working in cluttered areas can lead to accidents. Organizing your workspace allows for smoother operation.

Lastly, never underestimate the power of practice. Rushing through tasks can lead to mistakes. Take the time to refine your technique. Analyze what works and what doesn’t. Reflection is key. Each session offers insights that can enhance your efficiency. But be prepared to face challenges. Embrace them as learning opportunities.

Maintaining a manual chain is crucial for ensuring its efficiency. Regularly inspecting the chain for wear and tear is important. Look for signs of rust or damage. A clean chain performs better. Use a gentle cleaning solution with water. Avoid harsh chemicals that might corrode or weaken the chain. After cleaning, dry it completely. Moisture can lead to immediate rust formation.

Lubrication is key for optimal performance. Use a suitable lubricant that penetrates well. Apply it evenly along the chain. Wipe off any excess to prevent attracting dirt. It's essential to grease the chain after every few uses. Skipping this step can result in decreased performance and more friction. Additionally, check the tension regularly; a loose chain can lead to slippage. A tight chain can strain other components and lead to early wear and tear.

Keep storage conditions in mind too. Humidity can damage the chain quickly. Store it in a dry place, away from direct sunlight. Avoid leaving it outdoors. Be mindful of how often you use the chain. Frequent use demands more frequent maintenance. Sometimes, people forget these simple steps. This neglect can lead to inefficiency. A little attention goes a long way. Regular checks and maintenance help prolong the life of your manual chain.

When using a manual chain, safety is crucial. Always wear protective gear. This includes gloves, safety glasses, and sturdy footwear. These items help prevent injuries when handling heavy loads. Familiarize yourself with the operation manual. It may contain specific guidelines tailored to your equipment.

Tips: Inspect the chain regularly. Look for wear and tear. A worn chain can snap unexpectedly. Ensure the area around you is clear. Remove any obstacles that may cause tripping. Stay alert while operating the chain to avoid accidents.

Breaks are important. If you feel fatigued, take a moment to rest. Fatigue can lead to poor judgment and mistakes. Secure loads properly before lifting. Improperly secured loads are a common cause of injury. Always double-check your setup before operation.

| Aspect | Details |

|---|---|

| Manual Chain Type | Chain Hoist |

| Lift Capacity | Up to 5 tons |

| Chain Length | 6 meters |

| Material | Steel Alloy |

| Safety Load Limit | 1.5 times the maximum capacity |

| Inspection Frequency | Every 6 months |

| Common Hazards | Overloading, improper use, mechanical failure |

| Essential Safety Gear | Hard Hat, Gloves, Steel-Toed Boots |

| Training Required | Yes, operator training |

| Best Practices | Regular inspection, proper lifting techniques, secure load attachment |