Inquiry

Form loading...

-

E-mail

-

Whatsapp

When it comes to lifting heavy objects with ease and efficiency, a hydraulic hoist is an invaluable tool. These devices utilize hydraulic power to deliver impressive lifting capabilities while maintaining safety and stability. Selecting the best hydraulic hoist for your specific needs can significantly enhance your productivity and reduce the risk of accidents. With so many options available on the market, understanding the key features and factors to consider is essential for making an informed decision.

In this guide, we will highlight the top 10 tips for choosing the hydraulic hoist that best aligns with your requirements. From understanding lifting capacities and reach to evaluating safety features and maintenance needs, each element plays a critical role in ensuring that you select a hoist that not only meets but exceeds your expectations. Whether you are a seasoned professional or a first-time buyer, this comprehensive overview will equip you with the knowledge needed to navigate the choices available and invest wisely in a hydraulic hoist that supports your operations effectively.

Understanding the different types of hydraulic hoists is essential for selecting the right equipment for various applications. Generally, hydraulic hoists can be categorized into two main types: portable and stationary. Portable hydraulic hoists are designed for convenience and mobility, making them ideal for tasks that require flexibility, such as construction and maintenance work in multiple locations. These hoists typically feature compact designs and are lightweight, allowing for easy transport and setup. They are especially useful in tight spaces where larger equipment may not fit.

On the other hand, stationary hydraulic hoists are designed for heavy-duty applications in fixed locations, such as manufacturing facilities or warehouses. These hoists are usually more powerful, capable of handling larger loads, and are often integrated with existing machinery. They provide greater stability and reliability for repetitive lifting tasks and are ideal for environments where high load capacities and precision are paramount. Understanding these distinctions helps in making an informed choice based on the specific requirements of your projects, ensuring that you select a hydraulic hoist that aligns perfectly with your operational needs.

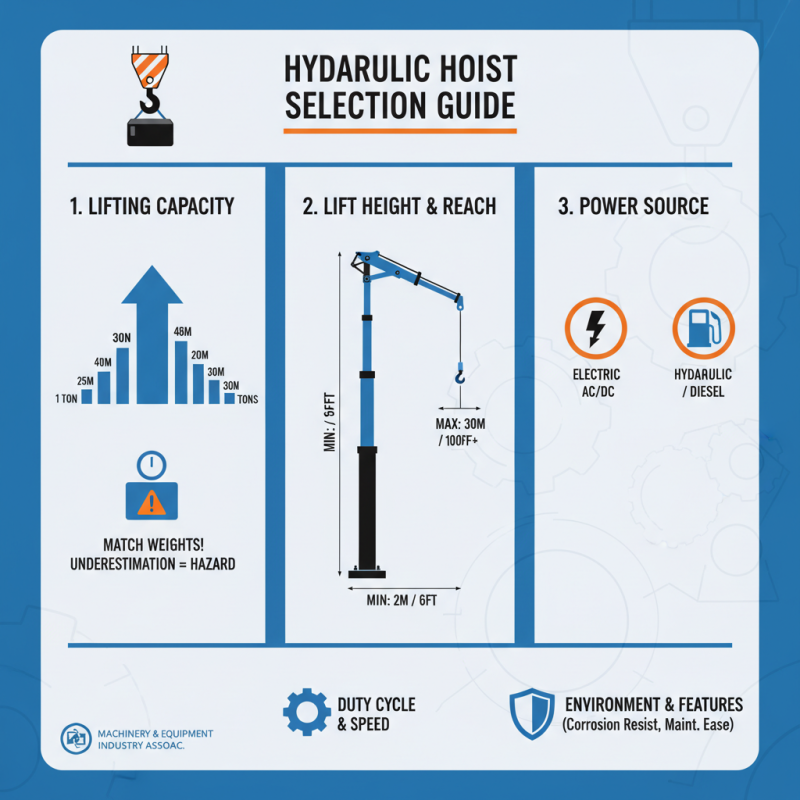

This chart displays key specifications to consider when choosing a hydraulic hoist, including load capacity, maximum lifting height, operation speed, weight, and price. Understanding these parameters can help you make an informed decision based on your specific needs.

When selecting a hydraulic hoist, several key factors must be weighed to ensure that the chosen equipment meets your specific needs. First and foremost is the lifting capacity. Understanding the weight of the items you plan to lift is crucial; most industry reports indicate that hydraulic hoists come in various capacities, typically ranging from 1 ton to upwards of 30 tons. A recent analysis from the Machinery and Equipment Industry Association highlighted that underestimating lifting capacity is a common error that can lead to equipment failure or operational hazards.

Another essential factor is the design and portability of the hoist. If your project requires moving the hoist frequently, opt for a model that is lightweight and easy to maneuver. According to research by the National Safety Council, mobility plays a significant role in maintaining workplace safety, as stationary hoists can create trip hazards if not placed correctly. Additionally, consider the hoist's hydraulic system type; double-acting cylinders are often favored in high-efficiency applications, while single-acting cylinders offer simplicity and ease of use for lighter tasks.

Lastly, maintenance and serviceability should not be overlooked. Regular maintenance is essential for longevity and safety; reports from the American National Standards Institute suggest that hydraulic systems require checks on fluid levels, leaks, and overall integrity every six months. Choosing a hoist designed for easy access to its hydraulic components can significantly reduce downtime and enhance operational efficiency, paving the way for safer lifting operations.

When selecting a hydraulic hoist, one of the most critical factors to consider is the load capacity requirements that match your specific needs. It's essential to accurately calculate the weight of the items you intend to lift, taking into account any additional factors such as safety margins and dynamic loads that may occur during operation. Overloading a hoist can lead to serious safety hazards, equipment failure, and costly downtime. Therefore, reviewing the maximum load capacity is vital to ensure that the hoist operates safely and efficiently within its designated limits.

Beyond just the maximum load, it's also important to consider the type of materials and shapes you will be lifting, as they can influence how the weight is distributed. Different hoists come with varying capacities and attachments that cater to specific lifting tasks. By understanding the intricacies of your lifting requirements, you can choose a hydraulic hoist that not only meets the load specifications but also improves overall productivity and safety on the job. Prioritizing load capacity during your selection process will ultimately lead to better performance and longevity of your hydraulic lifting solutions.

When selecting a hydraulic hoist, one of the most critical factors to consider is its safety features. Effective safety mechanisms can prevent accidents and ensure the well-being of operators and bystanders. Look for hoists equipped with overload protection, which automatically disengages the lifting mechanism if the load exceeds its capacity. This feature is crucial in avoiding equipment failure and potential injuries, making it a top priority in your selection process.

Additionally, consider hoists that offer emergency stop buttons easily accessible to the operator. This allows for immediate halting of the hoisting process in the event of an unexpected situation, enhancing response time during emergencies. Other important safety features include fail-safe braking systems that securely hold the load in case of power failure or malfunction. Furthermore, check for certifications and adherence to safety standards, which indicate that the hoist has undergone rigorous testing and meets industry guidelines. By focusing on these safety aspects, you can make a more informed decision when choosing the right hydraulic hoist for your specific needs.

When selecting a hydraulic hoist, maintenance and durability are crucial factors that can significantly affect its long-term performance and safety. According to a report by the International Association of Machinery and Maintenance, regular maintenance can enhance the lifespan of hydraulic equipment by 30% to 50%. This includes routine inspections to ensure that hydraulic fluid levels are adequate and that there are no leaks or seal wear, which are common issues that can diminish hoist performance. Keeping the hoist clean and free from debris also prevents wear and tear on moving parts, further prolonging its operational life.

Moreover, the choice of materials used in the construction of the hydraulic hoist plays a pivotal role in its durability. A study from the Engineering ToolBox highlights that hoists constructed from high-strength steel or aluminum alloys face less degradation over time compared to those made from lower-grade materials. These robust materials are often more resistant to corrosion and fatigue, which are critical considerations, especially in harsh environments. Implementing a proactive maintenance schedule not only ensures compliance with safety standards but also leverages the durability advantages of quality materials, ultimately leading to improved efficiency and reduced replacement costs.