Inquiry

Form loading...

-

E-mail

-

Whatsapp

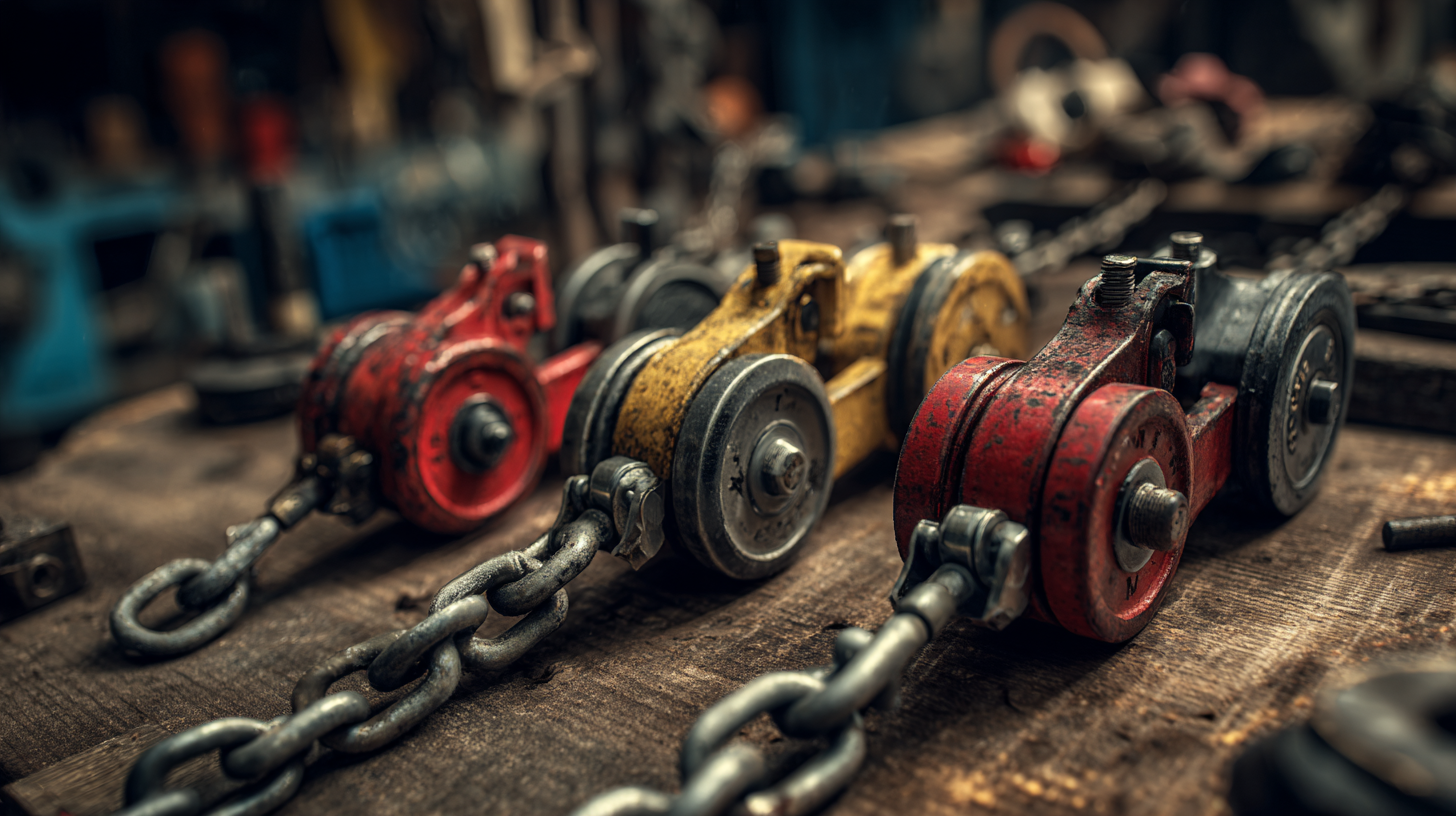

When it comes to enhancing productivity and safety in workshops, selecting the right equipment is paramount. One critical tool that stands out in material handling is the Manual Chain Hoist. According to the Material Handling Industry (MHI) report, approximately 72% of warehouses and workshops rely on manual hoisting solutions due to their efficiency and simplicity. Manual Chain Hoists provide operators the capability to lift heavy loads with minimal effort, making them an indispensable asset in various industries, from construction to manufacturing.

However, the market for hoisting equipment is inundated with numerous options, each designed for specific tasks and environments. Understanding the essential factors in choosing a Manual Chain Hoist is crucial to ensure optimal performance and safety in your workshop. This article outlines five essential tips to guide you in selecting the ideal Manual Chain Hoist for your specific needs.

When selecting a manual chain hoist for workshop applications, understanding load capacity is paramount. The weight rating of a hoist directly affects its safety and efficiency. According to a report by the American Society of Mechanical Engineers (ASME), it's crucial to choose a hoist that can handle at least 125% of the maximum load you expect to lift. This provides a safety margin that accommodates potential overloads and ensures reliable operation.

In addition to the safety factor, considering the frequency of use and the types of materials being lifted is essential. The Industrial Truck Association notes that regularly used hoists should have a higher load capacity to withstand wear and tear. For instance, a hoist with a 1-ton load rating may be ideal for infrequent lifting tasks, while a heavy-duty option rated at 2 tons or more would be more suitable for workshops handling heavier materials or frequent lifts. Evaluating these factors can lead to informed decisions, enhancing both productivity and safety in your workshop environment.

| Load Capacity (lbs) | Hoist Weight (lbs) | Lift Height (ft) | Chain Length (ft) | Price ($) |

|---|---|---|---|---|

| 1,000 | 50 | 10 | 15 | 150 |

| 2,000 | 100 | 12 | 20 | 250 |

| 3,000 | 150 | 15 | 25 | 350 |

| 4,000 | 200 | 18 | 30 | 450 |

| 5,000 | 250 | 20 | 35 | 600 |

When selecting a manual chain hoist for your workshop, assessing the lift height requirements should be a top priority. The lift height directly influences the hoist's efficiency and its suitability for various tasks. To begin, it's crucial to evaluate the maximum height you will be lifting items. This includes considering the total distance from the floor to the beam or the lifting point and any future adjustments in your workshop setup. Make detailed measurements to ensure that the hoist can accommodate your specific needs without compromising safety or performance.

Additionally, understanding your typical load sizes can further refine your choice. If you regularly handle heavy items that require significant vertical clearance, opting for a hoist with an extended lift height is essential. Conversely, if your projects tend to involve shorter lifts, a more compact hoist may suffice. By aligning the hoist’s lift capabilities with your workshop's operational needs, you can enhance productivity while ensuring that you have the right equipment for the job at hand.

When selecting a manual chain hoist for workshop needs, material considerations are paramount, as they significantly impact the hoist's durability and performance. According to a report by the Hoisting Equipment Manufacturers Institute (HEMI), the material composition of a chain hoist can affect its weight capacity and lifespan. For instance, hoists made from high-grade steel often exhibit superior strength-to-weight ratios, allowing them to handle heavier loads without compromising safety. In contrast, products constructed from lower-quality materials may lead to premature wear and tear, potentially resulting in operational failures.

Moreover, the construction type of a hoist—whether it’s all-mechanical, semi-mechanical, or an electric variant—can further influence its performance under different operating conditions. A study published by the Occupational Safety and Health Administration (OSHA) highlights that manual chain hoists crafted from corrosion-resistant materials, such as stainless steel, not only maintain their structural integrity in harsh environments but also enhance the safety of lifting operations. In workshops exposed to moisture or corrosive substances, choosing a manual chain hoist designed with durable materials can ensure longer service life and improved operational efficiency, ultimately safeguarding both the equipment and the workers involved.

When selecting a manual chain hoist for workshop needs, lifting speed is a crucial consideration that impacts both efficiency and control. According to the Material Handling Institute's report, an optimal lifting speed typically ranges from 3 to 12 feet per minute, depending on the application. This range allows operators to manage the load confidently while ensuring that the hoist can complete tasks within a reasonable time frame. Choosing a hoist with a speed at the higher end of this spectrum can significantly increase productivity in environments where time is of the essence, while slower speeds may be beneficial for delicate operations requiring more precision.

However, balancing speed with control is essential. Excessive lifting speed can lead to operational risks, such as swinging loads or dropping items. A study from the Occupational Safety and Health Administration (OSHA) emphasizes the importance of operator training in mitigating these risks. Ensuring that workers are adequately trained to handle a manual chain hoist can help maintain control even at higher speeds. Therefore, assessing the specific needs of your workshop—in terms of load types, operational environment, and worker expertise—will guide you in selecting a hoist that optimally combines speed and safety.

When selecting a manual chain hoist, prioritizing safety features is crucial to ensure compliance with industry regulations and best practices. According to the Occupational Safety and Health Administration (OSHA), nearly 40% of workplace accidents involve lifting heavy loads, underscoring the importance of proper hoist selection. Opting for a hoist equipped with certified safety features such as overload protection, which automatically disengages when weight limits are exceeded, can significantly mitigate these risks.

Moreover, compliance standards set forth by organizations like the American National Standards Institute (ANSI) emphasize the need for specific testing and certification. The latest reports indicate that hoists should adhere to ANSI/ASME B30.16 standards for vertical lifting devices, ensuring they are rigorously evaluated for their load capacity and operational safety. Additionally, features such as dual braking systems and ergonomic handles not only enhance operational safety but also contribute to user efficiency, aligning with the industry's shift towards more reliable and user-friendly equipment. By focusing on these safety standards, workshops can create a safer working environment for all employees.

This bar chart illustrates the importance rating of various factors when selecting a manual chain hoist for workshop needs. The ratings are on a scale from 1 to 10, highlighting the significance of each dimension such as load capacity, lift height, safety features, compliance standards, and overall durability.