Inquiry

Form loading...

-

E-mail

-

Whatsapp

In today's fast-paced industrial environment, selecting the right Movable Hydraulic Lift is essential for maximizing efficiency and safety. Experts in the field emphasize the importance of understanding the specific requirements of your operations. John Smith, a renowned hydraulic systems specialist, notes, "Choosing the right hydraulic lift not only enhances productivity but also ensures the safety of your workforce." This statement underscores the critical nature of this decision-making process.

When considering a Movable Hydraulic Lift, various factors must be taken into account, including load capacity, mobility features, and operational environment. Each operational context presents unique challenges, making it vital for businesses to evaluate their needs comprehensively. This introductory guide will delve into the key criteria for selecting the most suitable Movable Hydraulic Lift, aiding businesses in optimizing their lifting solutions. Understanding these elements will not only lead to better investment decisions but also contribute to a safer, more efficient workplace.

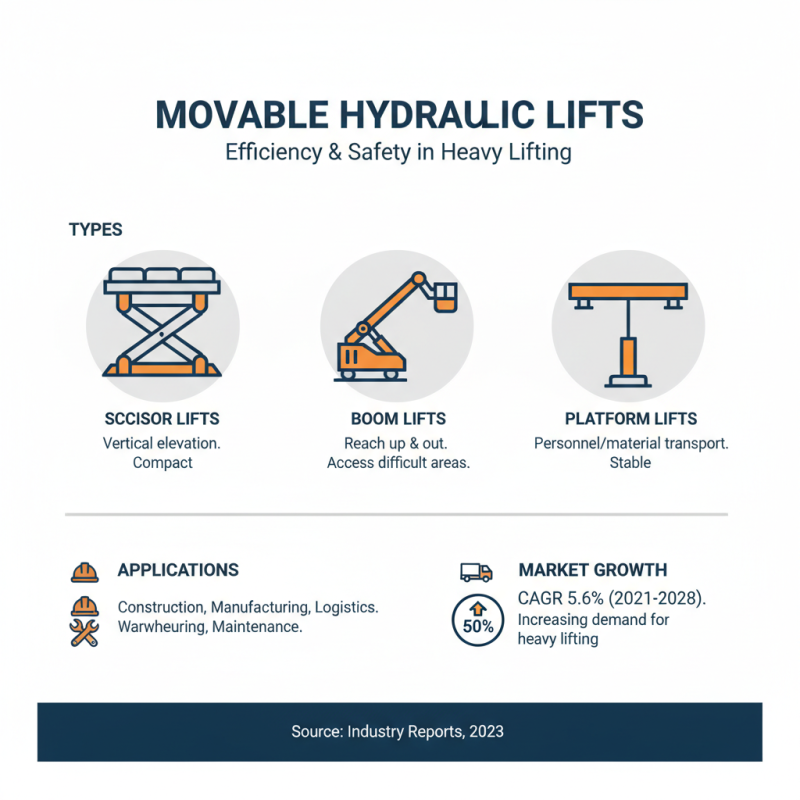

Movable hydraulic lifts are essential tools in various industries, offering increased efficiency and safety in transporting heavy objects. Understanding the different types and applications of these lifts is crucial for selecting the right one for your specific needs. Generally, movable hydraulic lifts are categorized into three primary types: scissor lifts, boom lifts, and platform lifts. According to industry reports, the global hydraulic lift market is projected to grow at a CAGR of 5.6% from 2021 to 2028, driven by the increasing need for heavy lifting equipment in construction, manufacturing, and logistics sectors.

Scissor lifts are known for their compact design and stability, making them ideal for indoor applications such as warehousing and retail environments. They typically have a lower height range, which suits applications like changing light fixtures or performing maintenance work. In contrast, boom lifts provide extended reach capabilities, making them perfect for outdoor applications, such as construction and tree care, where accessing high places is necessary. Platform lifts, on the other hand, are designed for accessibility and can be used in both commercial and residential environments to assist those with mobility challenges. Each lift type serves distinct functions, and understanding their specific applications can significantly enhance operational productivity.

Selecting the right movable hydraulic lift involves analyzing your operational needs and understanding the lifting capacities and height ranges required for your tasks. Industry experts recommend conducting a thorough site assessment to determine the lift type most compatible with your operational environment. By considering factors such as weight, reach, and maneuverability, operators can make informed decisions that align with their lifting requirements and enhance workplace safety.

When selecting the right movable hydraulic lift for your needs, several key factors come into play to ensure optimal performance and safety. Firstly, the lift capacity is crucial; most models can handle loads ranging from 500 to 5,000 pounds, but it's essential to evaluate your specific requirements. According to industry reports, choosing a lift with an adequate safety margin above the expected load is advisable to prevent accidents. Additionally, considering the platform size is important, as it must accommodate not only the weight but also the size of the items being lifted.

Another significant factor is the lift's mobility and stability. Hydraulic lifts should be easy to maneuver in confined spaces while providing solid support during operation. Research indicates that models with a wider base offer better stability, especially for heavier loads. Many hydraulic lifts now incorporate safety features such as overload protection and emergency stop buttons, which are vital for a secure work environment.

Tips: Always assess the terrain where the lift will be used; if the ground is uneven or inclined, a lift with adjustable legs might be necessary. Additionally, regularly reviewing and maintaining hydraulic systems is essential for longevity and performance, as data suggests that properly maintained lifts can last significantly longer than those that are neglected.

When selecting a movable hydraulic lift, the first step is to assess your specific load capacity needs. According to industry standards, the capacity of hydraulic lifts generally ranges from 500 to 10,000 pounds. However, it is crucial to consider not just the maximum weight but also how frequently the lift will be used for heavier loads versus lighter items. For instance, a study by the National Institute for Occupational Safety and Health (NIOSH) indicates that improperly estimating load capacity could lead to accidents, stressing the need for careful evaluation. Always ensure that the selected lift provides a safety margin above your anticipated requirements to accommodate dynamic load changes.

Size is another critical factor in the selection process of a hydraulic lift. The dimensions of the lift platform should align with the items being transported. The Occupational Safety and Health Administration (OSHA) recommends that lifts be at least as wide as the load being carried to maintain stability. Additionally, analyzing the available space is vital; the lift must fit within the operational environment without obstructing pathways or other equipment. In competitive environments, choosing a hydraulic lift that maximizes both load capacity and size can enhance productivity while ensuring safety and efficiency in material handling tasks.

When selecting a movable hydraulic lift, safety features and regulations should be at the forefront of your decision-making process. Hydraulic lifts are powerful tools, but they also come with inherent risks if not used correctly. It's essential to ensure that the lift you choose complies with local and international safety regulations, which often include standards set by organizations that focus on workplace safety. Check for certifications that demonstrate the lift has been tested for stability, load limits, and safe operation.

Tips: Always look for hydraulic lifts equipped with safety brakes, anti-slip surfaces, and automatic shut-off systems in case of malfunction. Additionally, ensure that the lift has visible and clear safety warnings and instructions. These features don't just protect users; they can also enhance overall operational efficiency.

Regular maintenance and inspections are also crucial for ensuring long-term safety. It is recommended to establish a routine check-up schedule to catch any potential issues before they become major problems. Training for operators on safe usage practices, load limits, and emergency protocols is equally vital. Empowering your staff with the knowledge to operate hydraulic lifts safely can significantly mitigate risks in the workplace.

This bar chart illustrates the importance of various safety features for movable hydraulic lifts based on industry standards and common practices.

When considering a movable hydraulic lift, budgeting is crucial to ensure that the investment aligns with both immediate needs and long-term financial planning. The initial cost of the lift can vary significantly based on its specifications, capacity, and features. It's important to outline your budget early in the selection process, identifying how much you're willing to spend while factoring in potential additional costs for customization or advanced functionality. A well-structured budget not only aids in the purchase decision but also helps in recognizing the trade-offs between price and quality.

Maintenance expenses are another vital aspect of budgeting for a hydraulic lift. Regular maintenance is essential to prolong the lifespan of the equipment and prevent costly repairs down the line. These expenses can include routine inspections, hydraulic fluid replacement, and servicing of mechanical components. By anticipating these costs and incorporating them into your overall budget, you can avoid financial surprises in the future. Conducting thorough research on the maintenance requirements and expected frequency can assist in making a well-informed decision that balances initial investment with sustained operational costs.