Inquiry

Form loading...

-

E-mail

-

Whatsapp

Selecting the right Hydraulic Cargo Lift for your business is crucial. The global market for hydraulic cargo lifts is expected to reach $3 billion by 2027, according to industry analyses. This growth highlights the importance of choosing the right lift to enhance efficiency and safety in your operations.

Consider the specific needs of your business. A hydraulic cargo lift must match the capacity required for your loads. Inadequate lifts can result in accidents or damage. A study by the Occupational Safety and Health Administration (OSHA) shows that improper lifting equipment contributes to over 30% of workplace injuries. This statistic underscores the necessity of making informed choices.

Evaluate features like lift capacity and height. Quality is paramount; not all hydraulic lifts are created equally. Some may disappoint in performance, leading to costly downtime. Investing in the right model can streamline your operations, but it requires thorough research. Reflect on your long-term needs and be wary of budget constraints that may lead to subpar choices.

Hydraulic cargo lifts are essential for many businesses. They enable easy movement of heavy goods. Understanding how they work can greatly influence your choice. These lifts use hydraulic systems to elevate loads efficiently. They can handle significant weight. This makes them valuable in warehouses, factories, and retail sectors.

For instance, a report by the Industrial Truck Association states that 33% of workplace injuries involve manual lifting. This highlights the importance of hydraulic lifts. They can significantly reduce physical strain on workers. Safety should always be a priority. Ensuring lifts are regularly maintained is crucial. A lift that isn’t working properly can pose safety risks.

Tips: When selecting a hydraulic lift, consider the weight capacity and dimensions. Assess your business needs carefully. Evaluate the workspace layout too. Compact designs might fit better in confined areas. Don’t rush the decision; this can lead to costly mistakes. Always consult with experts if unsure. You want to ensure the lift meets your specific requirements.

| Lift Type | Weight Capacity (lbs) | Platform Size (inches) | Max Height (feet) | Power Source | Typical Applications |

|---|---|---|---|---|---|

| Scissor Lift | 4000 | 60 x 40 | 12 | Electric | Warehouses, Construction |

| Platform Lift | 2500 | 48 x 48 | 8 | Hydraulic | Retail, Industrial |

| Freight Elevator | 10000 | 72 x 54 | 15 | Electric | Shipping, Heavy Industries |

| Mobile Lift | 1500 | 36 x 30 | 6 | Battery powered | Maintenance, Retail |

When selecting a hydraulic cargo lift, assessing load capacity is crucial. Many businesses overlook this key factor. The load capacity directly impacts safety and efficiency. According to industry reports, a significant portion of workplace accidents occurs due to inadequate load handling. In fact, improperly rated lifts can lead to costly damage.

Consider your typical loads. Are they consistent, or do they vary? It’s essential to calculate the maximum weight you'll lift, including additional materials. For example, lifts designed for 1,000 kg loads may fail under unexpected stress. This can lead to operational interruptions. Studies suggest that lifts with a better safety margin can reduce breakdowns by up to 30%.

It’s also vital to think about future needs. If your business plans to expand, select a lift with higher capacity. There may be hidden costs if you need to upgrade soon. Assessing not just current but anticipated needs can save time. Overall, while it might seem easier to choose based on initial requirements, long-term planning can prevent regrets later on.

This bar chart represents the availability of hydraulic cargo lifts based on different load capacity ranges. Understanding the load capacities can greatly assist businesses in selecting the appropriate hydraulic cargo lift for their specific needs.

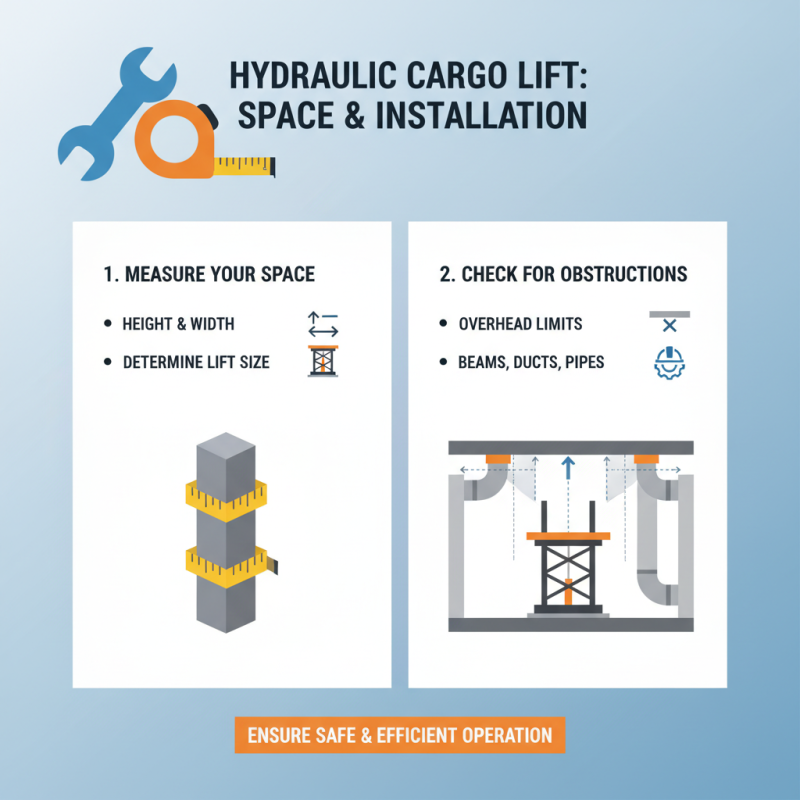

When choosing a hydraulic cargo lift, assessing space and installation constraints is crucial. Start by measuring the height and width of your area. This helps determine the lift's size. Make sure there’s enough room for the lift to operate safely and effectively. Consider overhead obstructions, like beams or ducts, that may limit installation.

Next, think about access points. Where will the lift be located? Is there enough space for loading and unloading? Narrow corridors or tight turns could pose issues. Evaluate the floor’s strength as well. It must support the lift and the weight it will carry.

Installation may require adjustments. This could mean reconfiguring existing spaces or even removing walls. Unexpected challenges often arise during installation. Perhaps the lift interferes with existing utilities. Anticipating these challenges can save time and resources. Space constraints can impact efficiency, so plan carefully. Prioritize a layout that enhances workflow and meets safety standards.

When selecting a hydraulic cargo lift, it's essential to evaluate the various types available on the market. For example, scissor lifts are popular due to their compact design. Their ability to elevate heavy loads makes them a staple in warehouses. However, they may not be suitable for very large items.

Another option is the vertical lift. These units are designed for tight spaces. They offer efficient vertical transport but might struggle with heavier loads. Organizations should consider the weight capacity of each lift type. It's a common mistake to underestimate the weight of the cargo.

Then there are mobile lifts, great for flexibility. They can be moved easily, which is a huge advantage. Yet, they might lack the stability of fixed models. Users should assess their workspace and operational needs carefully. This decision is crucial for operational efficiency and safety. Consider the potential for future needs as well. It often leads to reevaluating initial choices.

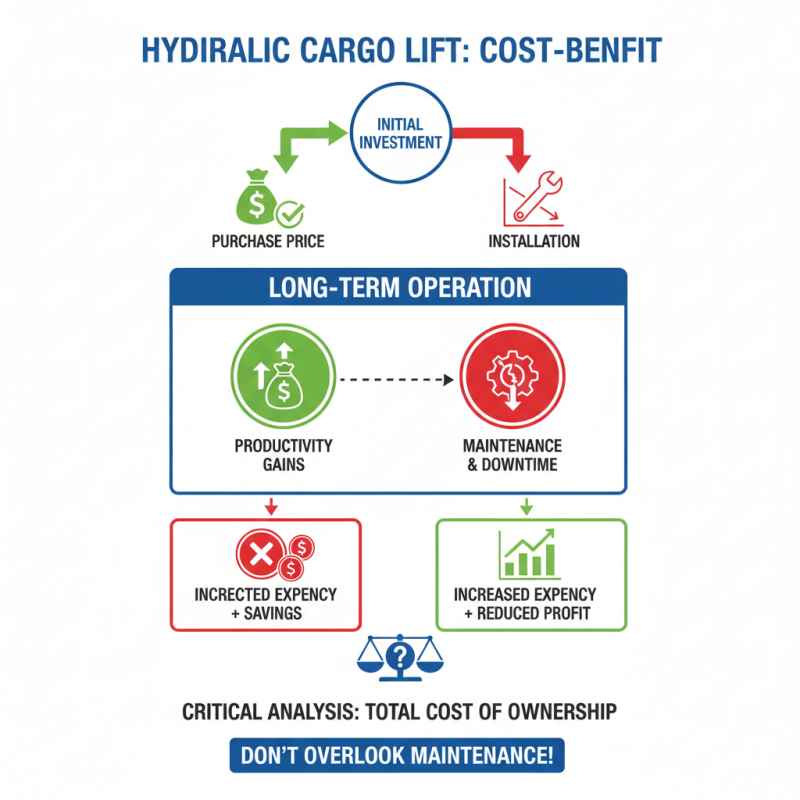

Choosing the right hydraulic cargo lift involves a critical analysis of its cost-benefit factors. Businesses often overlook maintenance needs, which can heavily affect long-term use. A lift may seem affordable initially, but high maintenance costs can add up quickly. Frequent repairs and downtime can hamper productivity and lead to unexpected expenses.

**Tips:** Regular maintenance checks are key. Establish a routine schedule for inspections. This will help catch issues early, saving money in the long run. Keeping records of servicing dates can also aid in tracking performance trends.

When evaluating models, consider their energy efficiency. Some lifts consume more power than others, impacting operational costs. Assessing lift design can help identify potential wear points. A lift that is easy to navigate may save time and energy when transporting goods.

**Tips:** Assess how many times you will use the lift daily. This helps in understanding the wear and tear process. It’s crucial to select a model that matches your operational pace. Failure to do so can lead to dissatisfaction and operational delays.