Inquiry

Form loading...

-

E-mail

-

Whatsapp

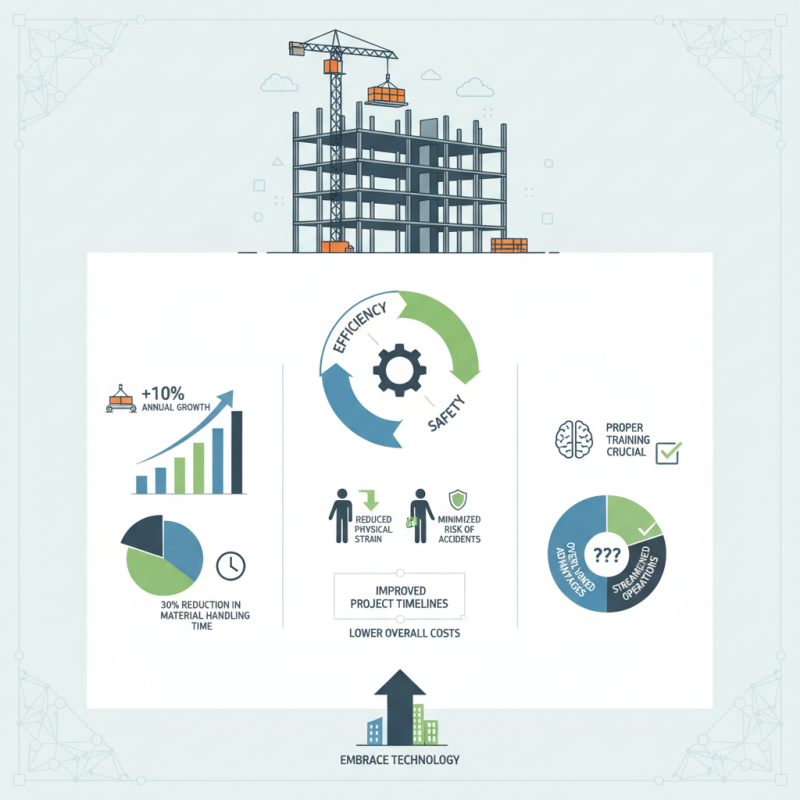

In the construction industry, efficiency and safety are crucial. Scaffold hoists play a significant role in achieving both. According to the Global Construction Market Report 2023, the demand for specialized lifting equipment, including scaffold hoists, is projected to grow by 10% annually. This rise indicates a growing recognition of their value in enhancing productivity on construction sites.

Scaffold hoists allow for easier movement of materials at various heights. This reduces the physical strain on workers and minimizes the risk of accidents. Industry studies show that using scaffold hoists can lead to a 30% reduction in time spent on material handling. This improvement directly influences project timelines and overall costs. However, it’s essential to ensure proper training for operators to maximize effectiveness.

Despite the clear advantages, some projects still overlook scaffold hoists. Misconceptions about their cost or complexity can lead to underutilization. Contractors should reflect on past mistakes and consider how scaffold hoists could streamline operations. Embracing this technology could significantly benefit future construction efforts.

Scaffold hoists are becoming increasingly popular in modern construction projects. They offer numerous advantages that enhance safety and efficiency on job sites. One significant benefit of using scaffold hoists is improved mobility. Workers can transport materials quickly to higher levels, saving valuable time. Traditional methods can slow down the workflow, leading to delays. Scaffold hoists eliminate much of that hassle.

Another advantage is the enhanced safety they provide. Lifting heavy materials by hand poses a risk of injury. Scaffold hoists minimize this risk, ensuring that workers can focus more on their tasks. This technology enables them to lift loads effortlessly. However, it's essential to use these hoists correctly to avoid accidents. Training is crucial, as improper use can lead to serious consequences.

Additionally, scaffold hoists contribute to better project organization. They keep the workspace clear. However, poor planning might still cause clutter, negating some benefits. It's a reminder that technology alone doesn't solve all problems. Effective teamwork is essential for maximizing the advantages of scaffold hoists in any construction project.

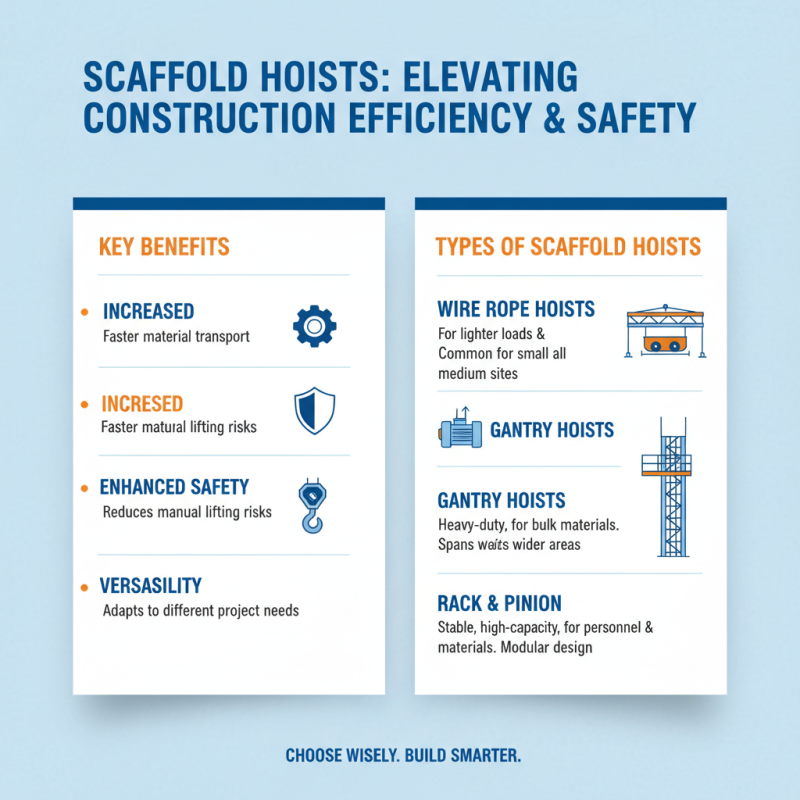

Scaffold hoists are essential for construction projects. They improve efficiency and safety. Various types of scaffold hoists cater to diverse needs. Understanding these can help in making informed decisions.

One common type is the electric scaffold hoist. These hoists lift heavy materials quickly. They save time and reduce the physical strain on workers. However, they require a reliable power source. In case of a power outage, projects can be delayed. Manual hoists offer another option. They are less expensive and don't depend on electrical systems. Workers may need to exert more effort, but they provide flexibility on site.

There are also material hoists, designed for specific tasks. They facilitate the transportation of heavy loads vertically. While they can handle large weights, the setup can be complex. Operators must be trained properly to avoid accidents. Choosing the right scaffold hoist involves careful consideration of project needs. Think about efficiency, safety, and worker comfort. Balancing these factors can lead to a successful project outcome.

When choosing scaffold hoists for construction projects, several features warrant careful consideration. Load capacity is paramount. Many construction professionals prefer hoists with a minimum capacity of 1,000 pounds. This ensures they can handle substantial materials efficiently. A report from the Occupational Safety and Health Administration (OSHA) indicates that overloading equipment remains a leading cause of accidents on job sites.

Another key feature is the lifting speed. A standard hoist can lift materials up to 30 feet per minute. Slower speeds can reduce productivity, yet safety should never be compromised. Quick lifts may lead to accidents, particularly in crowded work environments. Inadequate safety measures can result in serious injuries, impacting project timelines.

Durability is also crucial. Scaffold hoists are often exposed to harsh conditions. Materials should resist rust and wear. Regular maintenance is necessary, yet many workers overlook this. A survey found that 25% of contractors did not perform routine inspections on their lifting equipment. This negligence can have dire consequences. Each detail matters in ensuring both safety and efficiency in construction sites.

| Feature | Description | Benefits |

|---|---|---|

| Load Capacity | The maximum weight the hoist can safely lift. | Ensures safety and efficiency for heavy materials. |

| Speed | The rate at which the hoist can lift materials (meters/minute). | Improves work efficiency and project timelines. |

| Control System | Type of operator interface (e.g., remote control, push button). | Enhances ease of use and operational safety. |

| Durability | Quality of materials and construction of the hoist. | Reliable performance under various weather conditions. |

| Safety Features | Includes safety brakes, overload protection, and emergency stops. | Minimizes risks and ensures worker safety on site. |

| Mobility | Ease of moving the hoist from one location to another. | Facilitates quick setup and teardown, enhancing productivity. |

Scaffold hoists have become essential tools in construction. Their design enhances safety on job sites. When workers need to elevate materials, these hoists reduce the risks involved. The use of scaffold hoists minimizes dangerous manual lifting. This simple change leads to fewer injuries. Workers can focus on their tasks instead of worrying about heavy loads.

In addition to safety, scaffold hoists improve efficiency. They allow for a quicker setup and takedown process. This means that workers spend less time on logistics. Instead, they can dedicate their energy to actual construction work. However, this doesn’t eliminate the need for training. Understanding the equipment is crucial. Without proper knowledge, accidents can occur.

It’s also important to keep equipment well-maintained. Regular inspections can prevent unexpected malfunctions. Sometimes, even a small oversight can lead to significant issues. Not all job sites maintain equipment standards consistently. A proactive approach to safety can make a huge difference. Workers should always communicate any concerns they have.

When considering scaffold hoists for construction projects, cost-effectiveness becomes a crucial factor. Scaffold hoists can significantly reduce labor costs. They enable workers to transport heavy materials quickly and safely. This efficiency can lead to faster project completion. Compared to traditional scaffolding methods, the savings are notable.

Many alternatives, like ladders or manual hoisting, may seem cheaper. However, they often require more labor and time. Increased labor costs can outpace the initial savings. Using scaffold hoists minimizes the risk of worker fatigue and injuries. A safer site translates to fewer accidents and potential compensation claims.

Despite their benefits, scaffold hoists require initial investment and training. Proper setup and operation are essential for maximizing their value. Training may take time, and mistakes can happen. Investing in quality equipment and skilled labor pays off in the long run. It's vital to weigh the upfront costs against the long-term savings on labor and safety.

This chart illustrates the average cost per construction project when using scaffold hoists compared to traditional lifting methods. As shown, scaffold hoists provide a significantly more cost-effective solution, providing savings that can be used to enhance other aspects of the project.