Inquiry

Form loading...

-

E-mail

-

Whatsapp

As the demand for efficient lifting solutions continues to rise in various industries, the market for Micro Electric Hoists is experiencing significant growth. According to a recent report by MarketsandMarkets, the global electric hoist market is projected to reach USD 5.69 billion by 2025, growing at a CAGR of 5.3% from 2020 to 2025. This growth is driven by the increasing need for safety and productivity in material handling, making the selection of the right Micro Electric Hoist more critical than ever.

When choosing the best Micro Electric Hoist for your needs, considerations such as load capacity, lifting height, and operational efficiency are crucial. A survey conducted by IndustryWeek revealed that 78% of manufacturing professionals cited efficiency and reliability as the most important criteria when evaluating lifting equipment. With advancements in technology, modern Micro Electric Hoists now offer features such as enhanced control systems and compact designs, allowing even small businesses to optimize their lifting operations without sacrificing space or safety.

In 2025, as industries adapt to changing workloads and seek innovative solutions to streamline operations, understanding the key factors in selecting a Micro Electric Hoist is essential. This guide aims to equip businesses with the necessary insights to make informed decisions, ensuring they invest in a hoisting solution that meets their specific requirements while complying with industry standards and regulations.

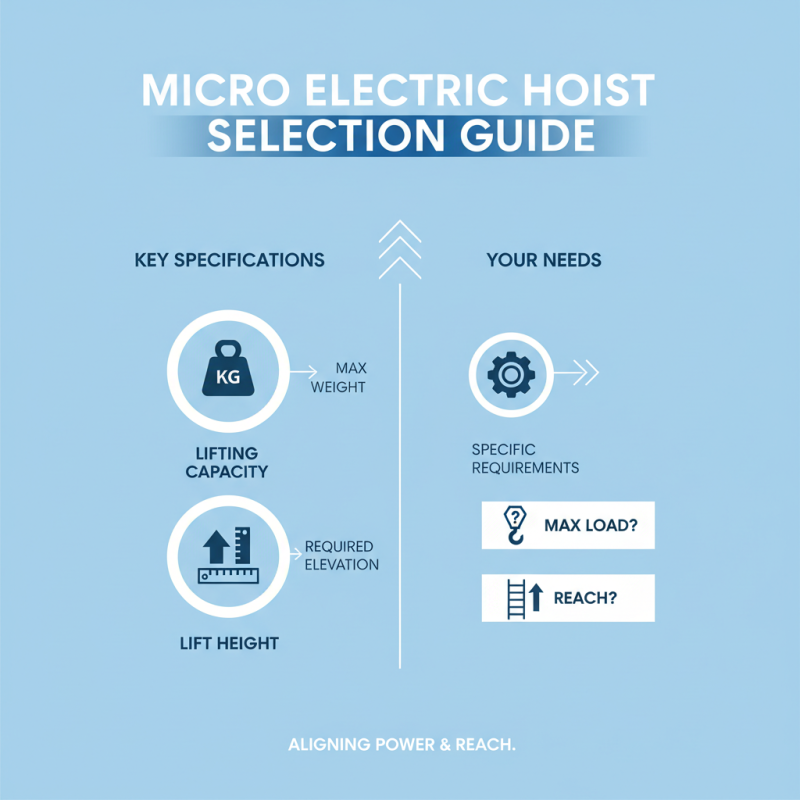

When selecting a micro electric hoist, several key factors should be taken into account to ensure the equipment meets your specific needs. First and foremost, consider the weight capacity of the hoist. It is crucial to choose a model that can safely handle the loads you intend to lift, as exceeding the weight limit can lead to equipment failure and pose safety risks. Additionally, take into account the lifting height required for your tasks – different hoists offer varying maximum heights, and selecting one that aligns with your operational requirements is essential.

Another significant consideration is the power source and motor efficiency of the hoist. Electric hoists are typically powered by different voltages, so assess your available power supply when making a decision. Look for features such as overload protection and thermal safety shut-off, as they can enhance the longevity of the hoist and provide an extra layer of safety during operation. Finally, portability and ease of installation are important attributes to review, particularly if you plan to use the hoist in multiple locations. A lightweight, compact design can facilitate easier transport and setup, ultimately improving your overall efficiency.

When considering the best micro electric hoist for your needs, understanding the various types available on the market is essential. There are primarily three categories of micro electric hoists: the portable hoists, the fixed hoists, and the industrial hoists. Portable hoists are designed for ease of use and mobility, making them ideal for home projects or small commercial tasks. According to a recent industry report by Grand View Research, the portable hoist segment is expected to experience significant growth, projected to reach a market size of approximately $1.2 billion by 2026 due to increasing demand in DIY industries and small-scale operations.

Fixed hoists, on the other hand, are often used in more permanent settings where heavy loads need to be lifted consistently. These are commonly found in factories or warehouses, where installation and durability are paramount. In fact, studies from MarketsandMarkets indicate that the industrial segment of electric hoists will continue to dominate the market, anticipating a growth rate of 6.5% through the next five years. This growth is largely attributed to advancements in technology, enhancing load capacity and safety features, which are particularly vital in high-demand sectors such as construction and manufacturing.

Finally, there are specialized micro electric hoists that cater to niche markets, such as medical or equipment handling applications. These hoists often include unique features tailored to specific tasks, which can enhance efficiency and safety. According to an analysis by Research and Markets, the rise in automation across various industries is driving the demand for specialized hoists, suggesting that understanding these variations and their capabilities is critical for making an informed choice in selecting the right micro electric hoist for specific operational needs.

| Type | Load Capacity (kg) | Lifting Height (m) | Power (W) | Weight (kg) | Price ($) |

|---|---|---|---|---|---|

| Chain Hoist | 250 | 20 | 600 | 10 | 150 |

| Wire Rope Hoist | 500 | 30 | 1200 | 15 | 300 |

| Electric Winch | 300 | 25 | 800 | 12 | 220 |

| Mini Electric Hoist | 150 | 15 | 400 | 8 | 100 |

When selecting a micro electric hoist, it’s essential to focus on key specifications that align with your specific lifting requirements. One of the primary factors to consider is the lifting capacity. Determine the maximum weight you will be hoisting, as micro electric hoists come with varying capacities to suit different tasks. It’s also crucial to assess the height of lift. Ensure that the hoist can reach the required elevation without strain, as inadequate lifting height can limit its functionality.

Another important specification is the speed of operation. Depending on your project’s urgency, a faster hoist may save significant time, but you must balance this with safety and control. Look for a model that offers adjustable speed settings to cater to different lifting scenarios effectively. Additionally, evaluate the construction and durability of the hoist. A robust design with high-quality materials can enhance longevity, especially in demanding environments. Consider factors like weight, size, and ease of storage, as these will also impact the overall usability of the hoist for your unique needs.

When selecting a micro electric hoist in 2025, safety features and compliance standards should be your primary focus. According to recent industry reports, nearly 50% of workplace accidents related to lifting equipment are attributed to equipment failure and lack of safety features. It is imperative to look for hoists equipped with essential safety mechanisms such as overload protection, which prevents the hoist from lifting beyond its rated capacity. Additionally, features like emergency stop buttons and safety latches can significantly reduce the risk of accidents during operation.

Compliance with safety standards is another crucial aspect to consider. In the United States, the Occupational Safety and Health Administration (OSHA) along with the American National Standards Institute (ANSI) set stringent regulations for lifting equipment. For example, hoists should meet the standards outlined in ASME B30.16, which specifies safety requirements for hoists. Internationally, adherence to ISO 4301-1 ensures that operators are using equipment designed with minimal risk in mind. By choosing a micro electric hoist that meets these standards, users can ensure that they are investing in equipment that not only enhances productivity but also prioritizes safety in the workplace.

This bar chart illustrates the importance levels of various safety features for micro electric hoists. The ratings on a scale of 1 to 10 highlight which features are deemed most critical for safe operation and compliance in 2025.

When considering the purchase of a micro electric hoist, budgeting and cost-effectiveness are pivotal factors that can significantly influence your decision. The market for micro electric hoists is projected to grow steadily, with reports indicating an average annual growth rate of around 6% from 2023 to 2028. This growth highlights the increasing adoption of these hoists across various industries, which underscores the importance of understanding their cost implications in your specific context.

One effective approach to budgeting for a micro electric hoist is to evaluate the total cost of ownership (TCO). This includes not only the initial purchase price but also operating costs, maintenance, and any potential downtime expenses. Data suggests that while the upfront costs of high-quality hoists may be higher, they often yield better performance and lower maintenance frequency, resulting in substantial savings over time. Investing in a more durable model can reduce overall expenditures in the long run.

Tips: When selecting a micro electric hoist, always compare the specifications and features of multiple models. Look for energy-efficient options that offer lower operating costs. Additionally, consider the warranty and support services provided, as these factors can significantly affect your maintenance budget and operational reliability.