Inquiry

Form loading...

-

E-mail

-

Whatsapp

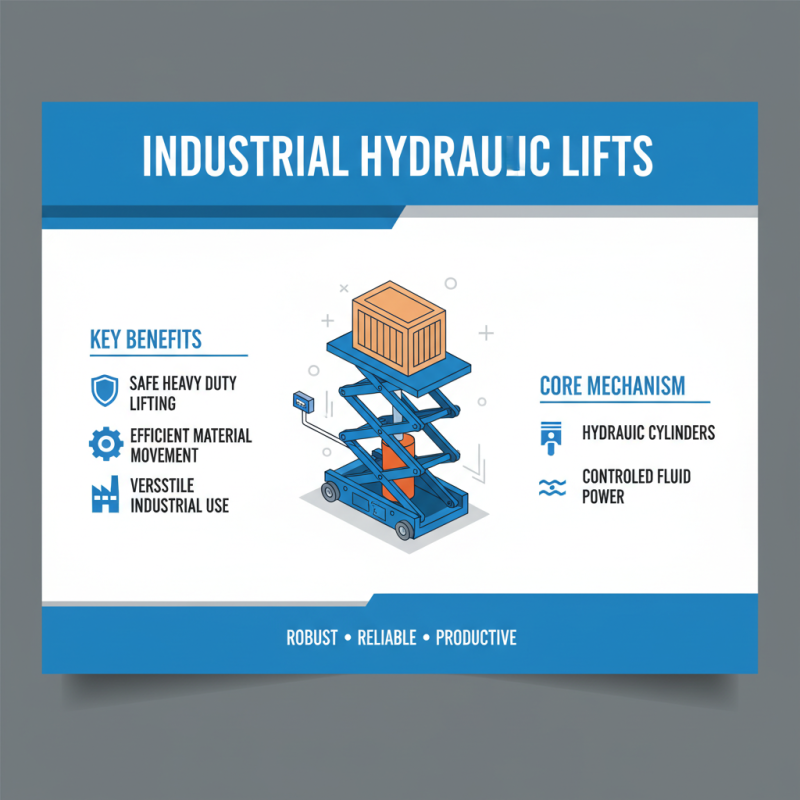

In the rapidly evolving landscape of industrial operations, the significance of an efficient and safe lifting solution cannot be overstated. This is where the Industrial Hydraulic Lift comes into play, offering unparalleled performance in various sectors, from manufacturing to warehousing. As industry expert Dr. Emily Carter explains, “The right hydraulic lift not only enhances productivity but also significantly reduces the risk of workplace injuries.”

This statement encapsulates the essence of this essential machinery, which provides both efficiency and safety to workers handling heavy loads. With advancements in technology and engineering, today’s Industrial Hydraulic Lifts are designed to meet the rigorous demands of modern industrial environments while ensuring maximum safety standards. In this article, we will explore the top ten Industrial Hydraulic Lifts that stand out for their exceptional quality, innovative features, and reliability, making them indispensable tools for any industrial setting.

Industrial hydraulic lifts are essential tools in various sectors, providing reliable solutions for lifting heavy loads safely and efficiently. These systems use hydraulic cylinders to raise and lower platforms, allowing for the smooth movement of materials and equipment in warehouses, factories, and construction sites. The design of these lifts often incorporates robust materials to withstand demanding tasks, while the hydraulic mechanism ensures a steady and controlled lift, minimizing the risk of accidents.

Understanding the mechanics behind hydraulic lifts is crucial for optimizing their performance. At the core of these systems is hydraulic fluid, which transmits force applied to levers or buttons to the lift mechanism. This enables operators to lift significantly heavier loads than they could manually. Additionally, modern hydraulic lifts are equipped with safety features such as overload sensors and emergency stop buttons, ensuring that they operate within safe parameters and reducing the likelihood of malfunctions. Regular maintenance and inspections are essential to keep these systems functioning correctly, further enhancing workplace safety and efficiency.

When selecting an industrial hydraulic lift, efficiency and safety are paramount. Key features that contribute to these aspects include load capacity, speed of operation, and ease of maintenance. A well-designed hydraulic lift should be capable of handling the required load with a margin of safety. This ensures not only the safety of the workers but also the integrity of the materials being lifted. Additionally, a lift that operates at optimal speed helps minimize wait times, thus enhancing overall productivity in the workplace.

Another critical feature to consider is the lift's safety mechanisms. Modern hydraulic lifts are equipped with various safety features, such as emergency stop buttons, overload protection, and anti-fall systems. These enhancements are essential in preventing accidents and injuries that could arise from equipment failure or operator error. It is wise to conduct regular inspections and maintenance to ensure that these safety features are always in working order.

Tips: Regularly train operators on the correct usage and safety protocols associated with hydraulic lifts. Additionally, assess the workspace to ensure that the lift is suitable for the environment, accounting for factors such as space constraints and flooring conditions. By prioritizing these features and safety measures, you can greatly enhance both the efficiency and safety of your hydraulic lifting operations.

When it comes to industrial applications, selecting the right hydraulic lift is crucial for enhancing productivity and ensuring safety in the workplace. The top hydraulic lifts are specifically designed to manage heavy loads, providing robust performance and reliability in various environments. These lifts often feature advanced hydraulic systems that offer smooth operation and precise control, which are essential for tasks demanding strict safety standards.

In addition to their functional benefits, modern hydraulic lifts come equipped with safety features that protect operators and equipment alike. This includes overload protection systems, emergency stop mechanisms, and tilt sensors that maintain stability during operation. The combination of high lifting capacities and safety enhancements makes these lifts ideal for warehouses, factories, and construction sites.

By investing in quality hydraulic lifts, industrial settings can achieve maximum efficiency while minimizing the risks associated with heavy lifting tasks.

When selecting industrial hydraulic lifts, it is crucial to prioritize safety standards and regulations to ensure a secure working environment. The Occupational Safety and Health Administration (OSHA) provides guidelines that operators and maintenance teams must follow to minimize risks. Regular inspections and adherence to manufacturer specifications are vital components in maintaining compliance with safety regulations. Additionally, training for operators on proper usage and handling of hydraulic lifts is essential in preventing accidents and injuries.

Tips: Ensure that all staff are trained properly on the specific hydraulic lift being used, including emergency protocols for scenarios such as power failures. Regularly review safety practices and conduct drills to keep these protocols fresh in everyone’s mind.

Another significant aspect of safety in hydraulic lifts is the use of protective equipment and features. Proper safeguards, such as guards or rails, should be in place to protect operators from falling loads or pinch points during operation. It's also advisable to implement a safety checklist that includes verifying load capacity and the condition of hydraulic systems before each use.

Tips: Develop a maintenance schedule that includes routine checks of hydraulic fluid levels and system integrity. Encourage operators to report any unusual sounds or performance issues immediately to minimize potential hazards.

| Model | Load Capacity (lbs) | Lift Height (ft) | Power Source | Safety Features | Compliance Standards |

|---|---|---|---|---|---|

| Model A | 5000 | 15 | Electric | Emergency Stop, Overload Protection | ANSI/ASME B30.1 |

| Model B | 8000 | 20 | Hydraulic | Guardrails, Emergency Lowering | OSHA 1910.178 |

| Model C | 6000 | 18 | Pneumatic | Safety Locks, Overload Sensors | ISO 13849-1 |

| Model D | 7000 | 25 | Electric | Emergency Stop, Safety Bar | ANSI B56.1 |

| Model E | 9000 | 22 | Hydraulic | Anti-Slip Surface, Safety Fencing | CE Marking |

Regular maintenance of industrial hydraulic lifts is crucial to ensure their optimal performance and enhance safety in the workplace. One key aspect of maintenance is conducting routine inspections, which should include checking for any signs of wear and tear, leaks, or unusual noises. Timely identification of potential issues can prevent accidents and costly repairs. Additionally, operators should maintain fluid levels and check the hydraulic system for proper functioning, as this directly impacts lift efficiency.

Another essential tip for maintaining hydraulic lifts is to ensure that all safety features, such as emergency stops and warning lights, are operational. It is recommended that employees are trained to conduct these checks and understand the importance of these features. Furthermore, the lift's overall cleanliness should be maintained, as debris can affect both performance and safety. By establishing a regular maintenance schedule and encouraging operator responsibility, workplaces can significantly reduce the risks associated with the use of industrial hydraulic lifts.