Inquiry

Form loading...

-

E-mail

-

Whatsapp

The advancements in technology have led to the rise of the Movable Hydraulic Lift. This equipment is essential in various industries. Its versatility and efficiency make it a valuable asset for many operations.

Movable hydraulic lifts come in different sizes and capacities. Their ability to transport heavy materials with ease is impressive. They can be used in construction sites, warehouses, and even home settings. Additionally, their design allows for maneuverability in tight spaces, which is often a challenge for traditional lifts.

However, using these lifts is not without concerns. Safety measures must always be prioritized. Regular maintenance is crucial to ensure optimal performance. Evaluating the needs and technical aspects of a project is important before selecting the right model. Indeed, while Movable Hydraulic Lifts offer many benefits, potential drawbacks require careful consideration and reflection.

Movable hydraulic lifts are gaining popularity across various industries. They offer flexibility and ease of use. Users find these lifts beneficial for transporting materials between different levels. The design allows for smooth vertical movement, making them ideal for warehouses and construction sites.

One notable feature is their adjustable height. This adaptability helps in reaching various working heights. However, some operators struggle with proper setup. Ensuring stability is crucial to prevent accidents. Regular maintenance checks are essential. Users must face the challenge of keeping the equipment in optimal condition.

These lifts find applications in diverse settings like retail and manufacturing. They handle heavy loads with ease. The compact design fits into tight spaces, making them versatile. Yet, there may be limitations on load capacity. Users need to be aware of the specifications to prevent overloading. Evaluating the operational requirements is key to efficient lifting.

This chart illustrates some of the top features and applications of movable hydraulic lifts in 2026. The data represents crucial aspects such as lift capacity, common applications, lift speed, platform size, and safety features, reflecting the advancements and industry standards in hydraulic lift design.

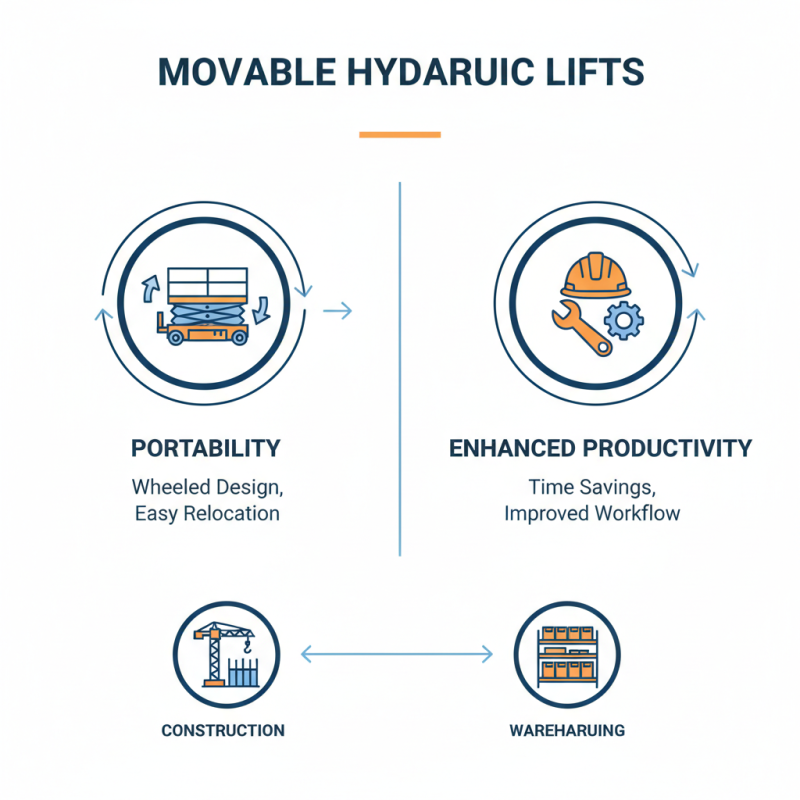

Movable hydraulic lifts have become essential in various industries, including construction and warehousing. These lifts offer unique features that enhance productivity. One of the key features is their portability. Thanks to their wheeled design, operators can easily move them to different work sites. This flexibility saves time and improves workflow.

Another important feature is their adjustable height. Many lifts can reach multiple levels according to task requirements. Users easily change the height with a simple control mechanism. However, depending on the model, the control systems can be complex. Operating them requires training to ensure safety and efficiency.

Tip: Regular maintenance is crucial for movable hydraulic lifts. Check hydraulic fluids and connections frequently. This keeps the lifts in optimal condition.

Despite their advantages, not all lifts are suitable for every task. Some models may lack weight capacity. Others may struggle on uneven surfaces. Always assess the job's demands before selection.

Tip: Research capacity limits and surface requirements thoroughly. This helps in choosing the right lift for your needs. Always keep an eye on operator safety.

Movable hydraulic lifts are increasingly used across various industries. They enhance operational efficiency, providing convenience and safety in different tasks. In warehouses, for instance, lifts are essential for transporting heavy goods between levels. According to the International Warehouse Logistics Association, 70% of warehouses use hydraulic lifts for better space management.

In construction, these lifts are crucial for reaching elevated areas safely. They allow workers to move materials upward quickly, reducing downtime. Recent studies show that companies can increase productivity by up to 30% using hydraulic lifts for site elevation tasks. Additionally, they help mitigate workplace accidents, which account for 25% of injuries in construction.

Tip: Regular maintenance is key. Check for any hydraulic leaks or reduced performance. Addressing these issues early can prevent costly repairs down the line. Using the right lifting equipment is essential; many industries may still rely on outdated lifting methods, which can be inefficient. Evaluating current practices is important for safety and productivity enhancements.

Safety standards play a crucial role in the design and operation of movable hydraulic lifts. According to the "Global Hydraulic Lift Market Report 2023," over 30% of lift accidents are attributed to safety failures. These accidents often result in severe injuries or fatalities. Compliance with safety regulations is not just a requirement; it’s a necessity to protect users and operators.

The American Society of Mechanical Engineers (ASME) has established rigorous standards for hydraulic lifts. These standards cover design, maintenance, and inspection procedures. For example, regular inspections should be carried out every six months. However, many companies fail to adhere to this guideline. Neglecting these inspections can lead to catastrophic failures. Operators must not only ensure their hydraulic lifts meet these regulations but also train employees on safety protocols.

While safety features like emergency stop buttons and overload protection systems are vital, they can’t guarantee absolute safety. Human error remains a significant factor. A study by the Occupational Safety and Health Administration (OSHA) found that improper training leads to misuse of equipment. Ensuring thorough training for all operators can minimize risks significantly. As the industry evolves, the focus must remain on compliance, training, and continuous improvement to enhance safety in hydraulic lift applications.

| Feature | Description | Applications | Safety Standards |

|---|---|---|---|

| Adjustable Height | Allows customization of lift height for various tasks. | Warehouse operations, Automotive repairs. | ANSI/HI 1.4 |

| Portable Design | Easily movable from one location to another. | Construction sites, Event setups. | OSHA 1910.179 |

| Load Capacity | Supports a wide range of weights up to several tons. | Manufacturing, Shipping and receiving. | ISO 13849-1 |

| Remote Operation | Can be operated remotely for increased safety. | Logistics, Hazardous material handling. | EN 60204-1 |

| Safety Features | Includes emergency stop buttons and safety locks. | All applications requiring safety measures. | ASME B20.1 |

The future of movable hydraulic lift technology is bright. Innovations are on the rise, making lifts more efficient and versatile. You will see developments in smart technology integration. Lifts will adapt to various environments, including factories and warehouses.

One significant change is the increased use of lightweight materials. These materials enhance lift portability and reduce energy consumption. Users can expect quieter operations too. However, transitioning to smart technology poses challenges. Not all operators may be ready for automation. Training and adjustments will be necessary.

Safety features are essential in new models. Improved sensors and emergency systems protect users. Yet, reliance on technology raises concerns about malfunctions. Human oversight remains critical. Balancing advanced tech with practical usability will be key to successful implementation. Upgrading systems might require more than just financial investment; it demands a cultural shift towards embracing new ways.